The Robotics & Automation Theatre will feature both case-study presentations from exhibitors focussing on the benefits delivered by their products along with seminars from industry thought-leaders and experts on the latest trends and developments in the robotics and automation market.

-

20 mins

- Why most automation programmes fail long before any robot arrives

- How to prepare planning, data, and operating models so automation can actually scale

- The leadership blueprint for delivering automation that improves service, cost, and resilience

SpeakersRichard Brentnall Group Logistics Director - Nomad Foods

-

20 mins

- Automation as a Strategic Lever, Not a Cost Tool

- The Rise of the Intelligent Warehouse

- The Structural Shifts Reshaping Warehousing

SpeakersBen Rose Solutions Consultancy Manager - LogisteX

-

20 mins

- Why many automation initiatives may fail to scale

- When intelligent automation adds real value

- Scaling automation responsibly

SpeakersPromise Akwaowo Process Automation Analyst - Royal Mail

-

20 mins

- Understand why process stability must precede robotics deployment

- Gain insight into practical production challenges

- Apply lean ways of thinking to deliver measurable and sustainable value

SpeakersMoe Sufian Robotics & Automation Engineer - Airbus

-

20 mins

-

Funding opportunities available through Innovate UK for robotics and automation

-

How challenge-led innovation links real industry needs with developer solutions

-

How companies can engage with Innovate UK’s programmes, testbeds and wider innovation ecosystem

SpeakersAgnes Wamagui Knowledge Transfer Manager - Robotics - InnovateUK

-

-

20 mins

- Automation Is Not About Storage. It’s About Control

- Integrated Systems Outperform Isolated Technologies

- Scalability Must Be Designed — Not Assumed

SpeakersAlex Christopher Automation Sales Manager - Mecalux

-

20 mins

-

Modelling perception and decision-making under uncertainty in AI systems

-

Learning and adaptation mechanisms for dynamic robotic environments

-

Translating cognitive-inspired AI models into practical robotics applications

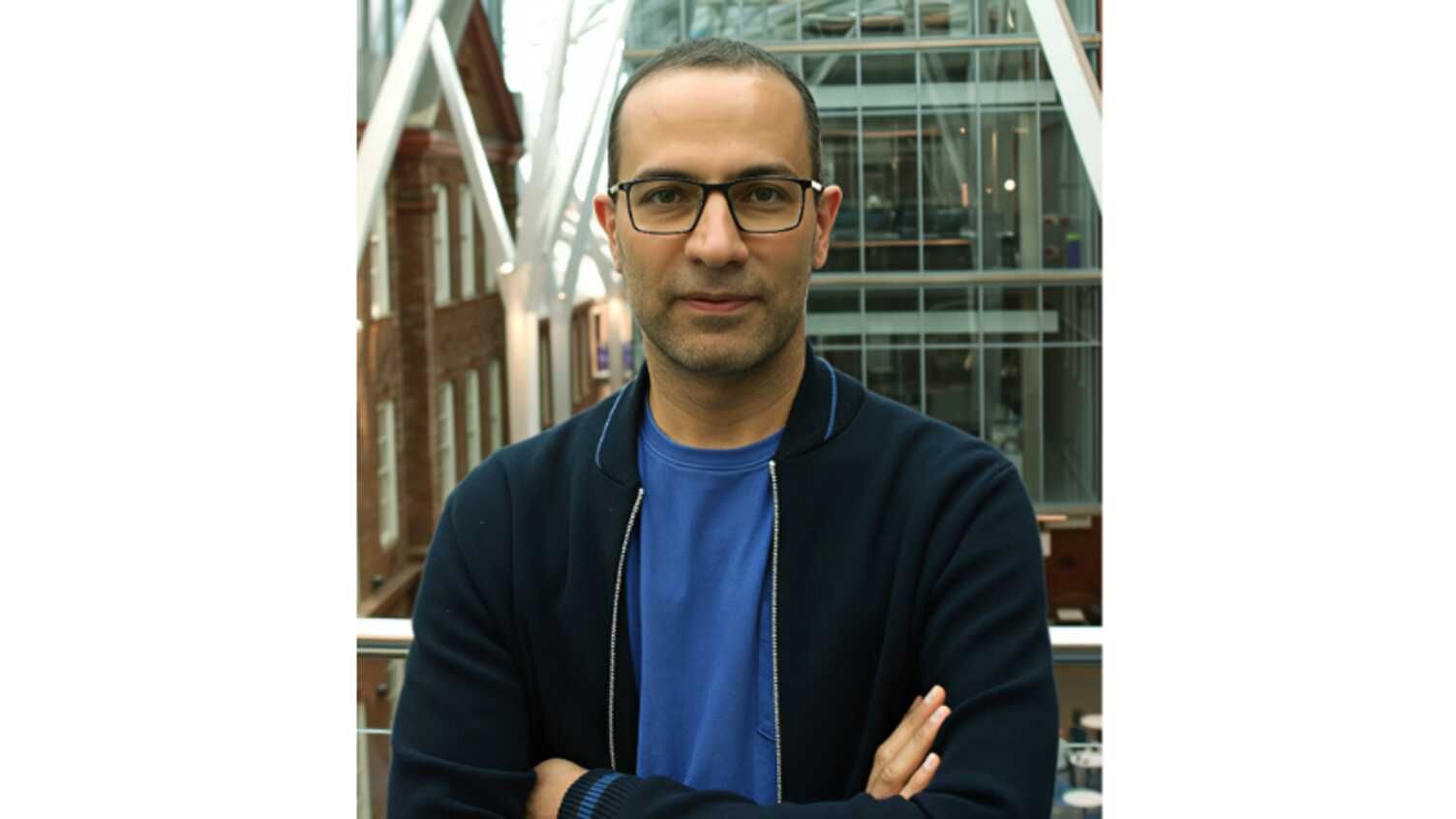

SpeakersFarhad Aghayev PhD Researcher - University of Edinburgh

-

-

20 mins

-

Swarm technology enables robots to be used out-of-the-box at scale

-

Advances in robotics, AI and collaborative awareness are powering swarm deployments

-

Applications range from manufacturing, construction, and farming to logistics

SpeakersSabine Hauert Professor of Swarm Engineering - University of Bristol

-

-

20 mins

-

Understand how foundational and world models differ from traditional task-specific automation approaches

-

Learn why prediction and anticipation are critical for robots operating next to humans

-

See how world models enable safer, more adaptive, and scalable automation in real-world environments

SpeakersProfessor Amir Ghalamzan-Esfahani Associate Professor of Robotics - University of Sheffield Theme Lead for Robotics & Autonomous Systems, Centre for Machine Intelligence (CMI)

-

-

20 mins

- End-to-end understanding of robotic manipulation systems

- Recent trends in building scalable, modular automation

- How digital twins accelerate testing, integration, and reliability

SpeakersRahul Ramachandran Robotics Engineer - The National Robotarium

-

20 mins

-

How robots can extract and learn dexterous manipulation skills from human multimodal data, including motion, tactile, and visual signals.

-

How multisensory AI, imitation learning, and reinforcement learning improve robotic autonomy, adaptability, and in-hand manipulation performance

-

Key challenges and solutions in transferring human manipulation skills to real robotic systems for industrial, assistive, and healthcare applications

SpeakersDr. Diego Resende Faria Associate Professor (Reader) - Loughborough University

-

-

40 mins

-

What is really holding the UK back?

-

What do the leaders do differently – and what can we copy intelligently?

-

A practical adoption roadmap for UK manufacturers and integrators

SpeakersAgnes Wamagui Knowledge Transfer Manager - Robotics - InnovateUK Nina Gryf Senior Policy Manager - Make UK

Nina Gryf Senior Policy Manager - Make UK

-

-

20 mins

-

Find out about the common problems facing SME manufacturers, how they address them, and how it reads across to your business

-

See case studies from companies that Made Smarter has supported with technology adoption

-

Take away practical tips to improve the planning and implementation of technology projects

SpeakersWill Kinghorn Technology adoption specialist - Robotics and Automation - Made Smarter

-

-

20 mins

- How digital twins and cyber-physical systems reduce deployment risk in regulated and high-consequence environments

- Why the “deployment gap” persists between research prototypes and field-ready robotic systems

- A practical academic–industry collaboration model that enables assured, long-term autonomy in demanding sectors

SpeakersPaul Dominick Baniqued Technical Project Manager - CRADLE Robotics and AI

-

30 minsThe Robotics & Automation Awards celebrate outstanding innovation, technical excellence, and real-world impact in robotics, warehouse automation, and intelligent systems across manufacturing and supply chain operations

-

20 mins

- Discover how flexible automation and adaptive software unlock new levels of efficiency and resilience

- See how intelligent batching, routing, and prioritization accelerate throughput and accuracy

- Learn how real-time data and workforce tools empower teams and sharpen decision-making on the floor

SpeakersChandru Palaniyandi Senior Software Engineer - Lucas Systems

-

20 mins

-

Attract investment in autonomous and AI-driven industries

-

Create high-skill local jobs in robotics and tech

-

Partner with industry & universities to drive innovation

-

-

20 mins

- Understanding of BSI

- Current robotic standards

- How to get involved

SpeakersTakiyah Williams Standards Development Manager - BSI Group

-

40 mins

- De-Risking Deployment

- Driving Operational Productivity

- Future-Proofing the Workforce

- Optimising Capital Investment

SpeakersCharlotte Lathbury Accelerated Digitalization and Innovation Manager - DHL Supply Chain Duncan Fleming Strategic Account Manager EMEA - Ocado Intelligent Automation

Duncan Fleming Strategic Account Manager EMEA - Ocado Intelligent Automation Matthew Wallis EU Director of Supply Chain - TMX Transform

Matthew Wallis EU Director of Supply Chain - TMX Transform Reuben Henry-Fellows Editor - Akabo Media

Reuben Henry-Fellows Editor - Akabo Media

-

20 mins

- Lowpad offers proven solutions, including a comprehensive Software Suite, which is key to controlling AMRs effectively and efficiently in their orchestration

- Lowpad Insights ensures operational transparency through analytics & dashboards – client owns data

- Lowpad Case Picking solution can significantly increase picking productivity and save time, £££

SpeakersMartijn Koudijs Accounts Director – UK&I - Lowpad

-

20 mins

- Understanding IFRA-Cranfield’s research vision and how current projects are advancing intelligent, flexible, and reconfigurable automation

- How a robot-agnostic ROS 2 framework enables standardised simulation, control, and rapid reconfiguration across different industrial and collaborative manipulators

- How ROS 2 and MoveIt!2 enable sim2real workflows and modular integration, supporting rapid robot cell deployment and seamless interaction with external hardware and software in adaptable manufacturing environments

SpeakersDr. Seemal Asif Senior Lecturer in Artificial Intelligence and Robotics - Cranfield University Mikel Bueno Viso Researcher in Intelligent Automation - Cranfield University

Mikel Bueno Viso Researcher in Intelligent Automation - Cranfield University

-

20 mins

- Key ethical concerns in Robotics and AI include privacy and surveillance risks, safety and system reliability issues, and potential impacts on employment and the broader economy

- These risks are not inherent or unavoidable; responsible design and governance can mitigate them

- Robotics and AI can enhance ethical outcomes by improving safety, reducing workplace injuries, and promoting transparency and accountability

SpeakersSamia Nefti-Meziani OBE Professor of Robotics and AI - University of Birmingham

-

20 mins

- Variable stiffness as a transformative design principle bridging rigid and soft robotics

- Integration of AI and advanced control with soft robotic systems systems

- Real-world impact in healthcare, industry, and autonomous mobility

SpeakersHelge Wurdemann Professor of Robotics - University College London

-

20 mins

-

Learn key concepts and methods used to define technology value-add

-

Gain knowledge on how to build a business case - for internal budgeting and project approval

-

Hear about real case studies describing benefits from IT system automation deployments

SpeakersSarah Dana Enterprise Director, Northern Europe - Rockwell Automation

-

-

20 mins

-

Harnessing BioEnergy: Microbial Fuel Cells (MFCs) convert organic matter into electricity using microorganisms, providing a sustainable and self-sufficient power source for environmental robots.

-

Waste to power: By utilising waste streams or natural substrates, MFC-powered Envirobots can clean, monitor, inspect environments while generating energy, reducing reliance on conventional batteries.

-

Sustainable Design: Understanding how to optimise MFC efficiency, use ceramic materials, and integrate them into robotic platforms is key for real-world deployment in remote environments.

SpeakersDr Iwona Gajda PhD, MSc, FHEA Senior Lecturer: Environmental Engineering/Project Management - UWE Bristol

-

-

20 mins

- Embodied AI agents will require organisations to redefine their strategy

- The convergence of agentic AI and robotics will drive considerable change

- Organisation survival will be determined by those leaders who can lead transformation

SpeakersProfessor Ashley Braganza PhD, MBA, CAIB, FBAM Professor of Business Transformation and Director, Centre for AI - Brunel University of London

-

20 mins

- Designing palletising systems for reliability, not just throughput

- Digital integration as a critical reliability layer

- From automated to autonomous palletising

SpeakersKaustubh Raut Process Engineer - Advanced Automation & Manufacturing Systems - McCormick UK

)

)