ROLLON RETHINKS ITS LINEAR ACTUATORS: TECHNOLOGICAL SIMPLIFICATION OFFERS NEW OPPORTUNITIES FOR INDUSTRIAL DESIGNERS

)

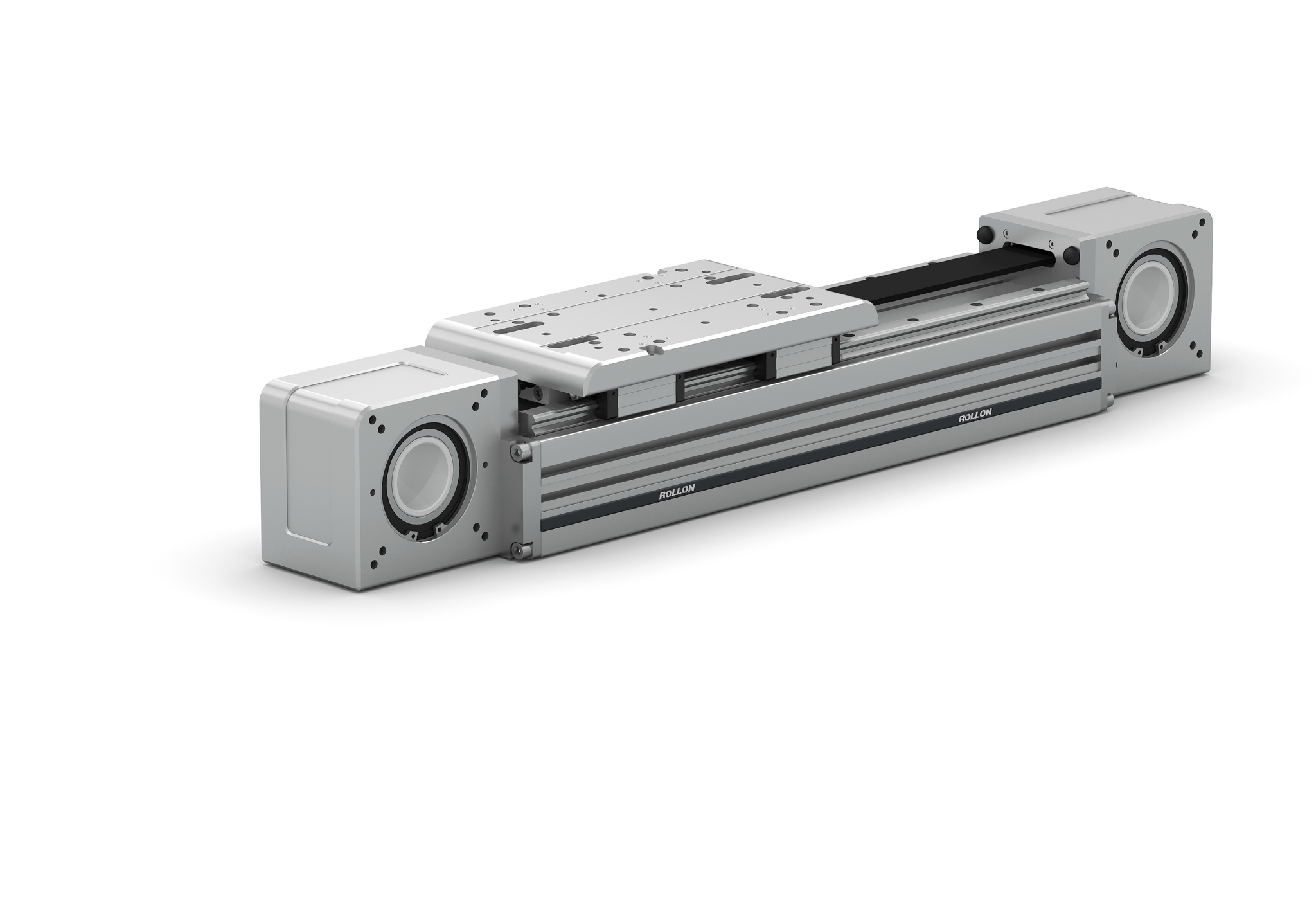

Important technical changes and a new design have been implemented on the Rollon Plus System actuators (ELM and ROBOT) and Smart System actuators (E-SMART and R-SMART), which became the first products in this line to take part in the technological and aesthetic redesign of the entire range of Rollon solutions. For both product families, dimensional interchangeability of old and new versions is guaranteed to ensure that the current performance of all solutions built to date remains unaltered.

New products, but with the same guarantees: Thanks to its 45 years of experience in the field, Rollon is able to offer customized solutions to fit the needs of each client without getting caught in the “unique product” trap. In combining a strongly industrialized construction phase with a final processing stage dedicated to the single need, Rollon unites production efficiency and scale economies with an artisan touch. This combination translates into mechanically integrated solutions that are tested and supplied by a single technological provider, which also handles support and maintenance at all levels. These are values that clients associate with optimized efficiency, a substantial reduction in production downtime in case of need, and the possibility of directing all their energy towards achieving their goals as they entrust Rollon with the design of the ideal linear motion system.

THE NEW PLUS SYSTEM

The Plus System family includes protected linear actuators with anodized aluminum profiles, self-supporting structures and toothed belt transmissions. The new version introduces a series of features that add significant efficiency and economic advantages for clients. The main features are:

- The introduction of a hollow shaft on the heads instead of those with integrated reduction gear mounting. Thanks to this new structure, the client can assemble the actuator and the gear motor directly, with a locking assembly in a fast and easy procedure, for which Rollon has prepared an on-line tutorial. The new hollow shaft will allow greater efficiency in terms of time, procedures and costs, for clients, and a real reduction in time to market.

- Now, clients can remove the cover belt without our intervention, thanks to the quick release of the block integrated into the flange that connects the profile and the actuator head. This operation has also become the subject of a specific on-line tutorial and, like the previous change, it is an innovation that reduces production downtime and maintenance time because it can be done without the intervention of Rollon’s technicians, whenever the client needs to.

These important technological changes are accompanied by a complete aesthetic review of the products in order to keep pace with the times and follow the main current industrial design trends – now attentive to the pleasantness of factory environments – which integrate with each project and maintain a distinctive feature that adapts well to the colors and lines of different application environments.

Aesthetically speaking, Plus System products now have a blue finish and radiated heads, instead of squarish heads. The white Rollon logo calls attention to the other products with the new design. An updated version of the carriage, with heads on both sides, has also been introduced.

These fresh changes and the lighter, more modern design are added to the performance levels that, through the years, have made these extremely robust and efficient products into reference points in the linear automation sector:

- Maximum sliding speed: 5 m/s

- Maximum acceleration: 50 m/s2

- Repeatability precision: ±0.05 mm

In addition to these characteristics:

- Plus System products are also available in a corrosion resistant version with profiles in extruded and anodized Anticorodal 6060 and 6082 aluminum, on which bearings, linear rails, bolts and components in low carbon content stainless steel are mounted.

- Both ELM and ROBOT are available in pressurized versions to preserve sliding quality in particularly contaminated environments.

- The square section of the anodized extruded aluminum profile used to make ELM is made in four sizes from 50 to 110 mm. The transmission uses a polyurethane toothed belt with steel inserts and the linear movement takes place on a rail with recirculating caged ball bearing blocks. A polyurethane belt seals the profile, hiding the transmission belt and the rails and ensuring complete protection from dirt, shavings, liquids and other contaminants.

- The rectangular section of the anodized extruded aluminum profile used to make ROBOT is made in four sizes from 100 to 220 mm. Linear movement takes place on a pair of rails with recirculating caged ball bearing blocks. The actuator is particularly suitable for applications with heavy loads, pushing and pulling of considerable masses, and stressful work cycles.

THE NEW SMART SYSTEM

The new features introduced in the Plus System product family are also present in the Smart System range, a family of linear actuators closely connected with the Plus family, which offer a very convenient price-quality ratio, high performance and a very simple and precise construction.

Products from the Smart line now have a black transmission belt and new carriages. These also have radiated heads, with a groove that gives a sense of continuity to the line formed by the transmission belt.

Also in this case, the performance of the new products has not changed, and guarantees:

- Maximum sliding speed: 4 m/s

- Maximum acceleration: 50 m/s2

- Maximum repeatability precision: ±0.1 mm.

An important point is that E-SMART series actuators have an extruded and anodized aluminum structure with a square section available in four sizes from 30 to 100mm. These linear actuators have transmissions with polyurethane toothed belts with steel inserts and translation on a linear rail with one or more recirculating ball bearing runners.

On the other hand, the R-SMART actuator is particularly suitable for heavy duty applications, which involve heavy loads, pushing and pulling of considerable masses, and stressful work cycles. With the use of two rails with recirculating ball bearings and the possibility of cantilever or portal mounting, these belt-driven linear actuators are the ideal solution for demanding applications on industrial automation lines.

REDESIGN, INTEGRATION INTO THE PROJECT TO OFFER PERFORMANCE AND DISCRETION

The presentation of the new Rollon products coincides with a revision of the aesthetics of the entire range, a process that began with the new Compact Rail products and the actuators in the Plus System and Smart System families, to then extend throughout the entire product catalog.

The redesign is a new step forward in Rollon’s history, which has been very intense, particularly in recent years. The company’s story includes growth, acquisitions, changes in ownership and development that affected its structure and products, leading to the creation of a version with softened stylistic features that can integrate, even aesthetically, into any project or application.

The new Rollon products combine the performance that has made them a reference point on the market, a distinctive and incisive aesthetic line, and the ability to integrate into any design process in the many different sectors where the company is present.

Technological and aesthetic redesign has allowed Rollon to express and affirm its unique identity as a major international player on the linear motion market.